isoCell Manual

Introduction

The isoCell greatly simplifies and automates the cloning of single cells, by allowing users to:

Create GRIDs on 60mm circular dishes.

Dispense single cells into GRID chambers (following the Poisson distribution).

Add cell-culture medium to GRID chambers, exchanging for waste products.

Harvest colonies.

Safety instructions

Use the isoCell with care, and take the following precautions:

Only use the isoCell once you have read and understood this manual. Ensure this manual is accessible for all users, and that each potential user reads and understands it.

Take all suitable precautions recommended for the safe handling of all cells and other reagents used. For the case of FC40star®, users should familiarise themselves with the FC40 material safety data sheet, which is available on the iotaSciences customer portal.

Powering the equipment:

Use only with the supplied Mean Well GST90A24-P1M power supply and power cord.

Connect power supply to a suitable AC mains supply with voltage in range 100 – 240V; 50 – 60Hz; minimum power 1A.

The AC mains socket shall act as the disconnect device and be readily accessible.

Avoid subjecting the isoCell to impact and vibration, both during use and during transportation.

Do not connect cables in ways other than those mentioned in this manual. Different connections may cause damage and fire.

Do not alter the isoCell in any manner, other than those shown in the manual, demonstrated during training, or directed by iotaSciences.

Do not obstruct the movement of the isoCell’s needle holder, nor of the syringe plunger mounts.

Only use the isoCell when it is set on top of a safe, flat and stable horizontal surface.

If water or other liquid has been spilled near the isoCell, safety may be compromised. Ensure that no spilled liquid has been in contact with or entered the isoCell.

If water or other liquid enters the isoCell, stop using it immediately and unplug the power supply. Continued use may cause a fire. Contact iotaSciences for actions or precautions.

If any foreign object enters the isoCell, safety may be compromised. Contact iotaSciences for actions or precautions.

Unplug the isoCell immediately if it smokes, or produces a strange odour or unusual noise. Continued use may cause a fire. Contact iotaSciences for actions or precautions.

Do not autoclave the isoCell.

The isoCell is designed to work between 16 – 35°C (60 – 95°F) and 40 – 60% humidity. Operating outside these limits may degrade performance and damage the isoCell.

All service shall be performed by iotaSciences authorised personnel only.

Getting started

Familiarisation

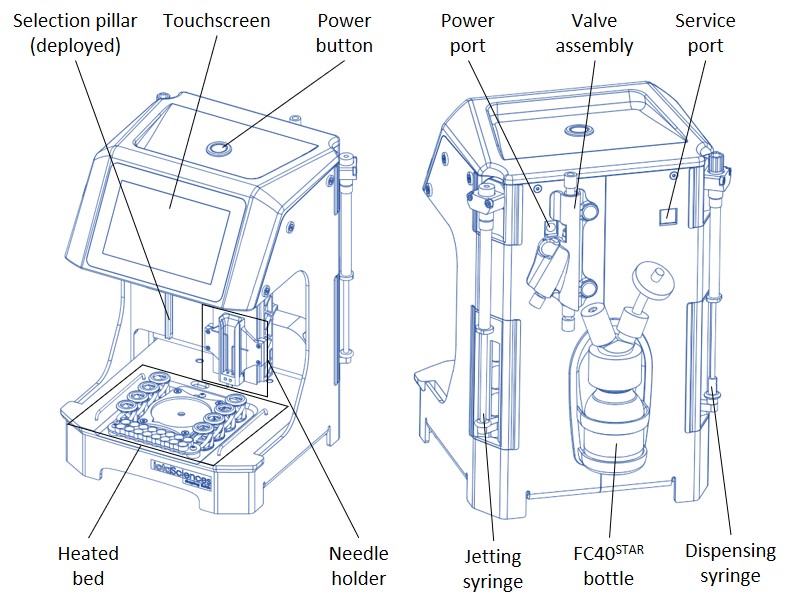

Users should familiarise themselves with the key components of the isoCell (Figure 1) prior to use.

N.B. the selection pillar is by default undeployed and therefore may not be visible.

The isoCell is supplied with the following accessories, consumables and spares:

Installation

The isoCell should be located on a flat, stable surface inside a laminar flow hood.

Upon first being powered-on, the isoCell will initiate a preliminary setup procedure. This consists of a sequence of on-screen instructions for the user to follow, and requires approximately 30 minutes to complete. Upon completion, the isoCell will be ready to use.

Using the isoCell

Powering-on

To power-on the isoCell, ensure that it is connected to a suitable mains power socket by the supplied mains power cable and 24V transformer. Press the power button (located on the top of the isoCell).

The isoCell bed – placement of reagents and materials

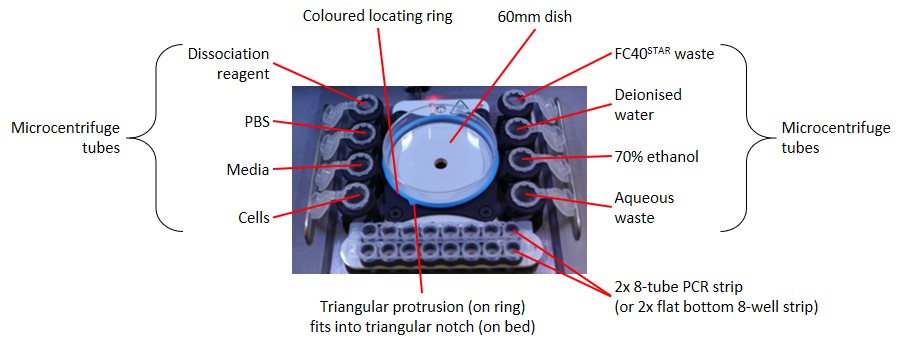

The isoCell bed (Figure 2) is where the workflow of isolating, culturing and harvesting cells is executed.

The workflow is executed on a 60mm tissue culture dish (supplied in the CloneG consumables kit). The dish must be placed in the circular station at the centre of the bed. It must be seated flat, and oriented such that the triangular protrusion of the locating ring fits into the station’s triangular notch (Figure 2).

The isoCell bed is equipped with an internal heater, which can be turned on or off in the options program.

N.B. The heater is not intended to hold the dish at precisely 37°C. Rather its purpose is to slow cooling when the dish is removed from an incubator.

When required by the workflow, user-supplied reagents must be placed in 1.5ml microcentrifuge tubes (supplied in the CloneG consumables kit) at six defined locations on the bed (Figure 2). A minimum of 1ml of each required reagent should be provided. Note that:

The isoCell will provide a visual prompt of the reagents required by any given part of the workflow.

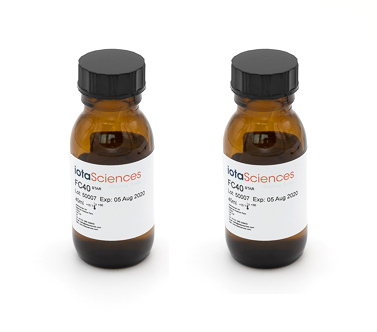

A seventh reagent, FC40star®, is stored in the FC40star® bottle at the rear of the isoCell (Figure 1).

Before beginning any program, ensure all microcentrifuge tubes are open with their lids tucked under the rails, as shown in Figure 2. This is essential to prevent obstruction of the needle holder.

Two further (empty) microcentrifuge tubes serve as repositories for aqueous and FC40star® waste. The isoCell will provide a visual prompt when waste microcentrifuge tubes are required. Users should ensure that waste tubes are empty.

For instructions on the safe disposal of FC40star®, refer to Disposal of FC40star®.

Cells are harvested by the isoCell from the 60mm dish into the two 8-tube PCR strips (or flat bottom 8-well strips) located at the front of the bed (Figure 2). The isoCell will provide a visual prompt when the PCR or flat bottom strips are required. The strips should be prepared with 120µl cell culture medium in each tube/well.

Do not put caps on the PCR strips.

Running programs

The isoCell workflow of isolating, culturing and harvesting cells is executed by running a series of programs on the isoCell. For instance, the GRID program will create a GRID on the 60mm dish, the plate program will dispense cells into a GRID, etc. All programs are executed from the isoCell’s interactive touchscreen. A stylus is supplied for higher touch accuracy when required.

At the beginning of each program, a message on the touchscreen will prompt the user to place the correct materials and reagents onto the isoCell bed. When providing reagents in microcentrifuge tubes, the user should fill the tube to a minimum volume of 1ml. When a waste tube is required, the user should ensure that the tube is empty.

Many programs require the user to select a username and dish colour. The isoCell supports up to thirty-six users. Under each username the isoCell can simultaneously track up to nine individual dishes via the dishes’ coloured locating rings. Stored user data can be managed via the data program.

Starting-up

Upon being powered-on, the isoCell will execute a startup routine.

Users should not skip the startup routine.

Restarting

To restart the isoCell, first press the on-screen ![]() button (located on the left side of the touchscreen). Then select the restart option, which will initiate a restart routine.

button (located on the left side of the touchscreen). Then select the restart option, which will initiate a restart routine.

The restart routine will put the isoCell into a fresh state. It is recommended that when switching users, the new user restarts the isoCell in this way.

Powering-off

To power-off the isoCell, first press the on-screen ![]() button (located on the left side of the touchscreen). Then select the shutdown option, which will initiate a shutdown routine. At the end of the shutdown routine, the isoCell will indicate that power can be safely switched off. At this point the user should power-off the isoCell by pressing the power button (located on the top of the isoCell).

button (located on the left side of the touchscreen). Then select the shutdown option, which will initiate a shutdown routine. At the end of the shutdown routine, the isoCell will indicate that power can be safely switched off. At this point the user should power-off the isoCell by pressing the power button (located on the top of the isoCell).

Users should not skip the shutdown routine.

Consumables ordering

To order consumables for the isoCell (CloneG kits and FC40star®), please visit the consumables store on the iotaSciences customer portal to obtain an instant quote.

Workflow

The isoCell offers a convenient and user-friendly workflow to achieve consistent and reliable outcomes from single-cell cloning experiments. It enables users to:

Isolate single cells

Culture and outgrow single cells into populations/colonies

Harvest populations/colonies derived from a single cell

The isoCell supports up to thirty-six users. Under each username the isoCell can simultaneously track up to nine individual dishes via the dishes’ coloured locating rings.

The isoCell quickstart user guide provides a concise overview of the isoCell workflow. The isoCell training guide provides a more detailed introduction to the isoCell workflow for new users. Both documents are supplied with the isoCell, and available for download from the iotaSciences customer portal.

Isolate

Cells are isolated in three stages:

The GRID program is used to form a 256 chamber GRID on a 60mm tissue culture dish, with each chamber measuring 1.9mm by 1.9mm.

The plate program is used to dispense 200nl cell-suspension fluid to each of the GRID’s 256 chambers.

The input data program is used to store, in the isoCell’s memory, the GRID-coordinates of chambers containing single cells.

GRID

To form a GRID, the user must first prepare the tissue culture dish with a coating of cell culture media/supplement formulation, overlaid with FC40star®.

Detailed dish-preparation protocols for specific cell culture media/supplement formulations are available on the iotaSciences customer portal.

For successful GRID formation, ensure that the relevant dish preparation protocol is followed correctly. Once prepared, place the dish onto the isoCell bed and run the GRID program.

Plate

To plate cells, the user must first prepare a 1.5ml microcentrifuge tube containing a sample of cell-suspension fluid with a dilution ratio of 5000 cells per millilitre.

For detailed instructions on best practice when preparing the cell-suspension, refer to the single-cell suspension preparation guidelines (available on the iotaSciences customer portal).

The plate program will dispense the cell-suspension fluid to the GRID chambers. The probability of chambers containing a single cell is determined by Poisson statistics. A dilution ratio of 5000 cells per millilitre maximises this probability, and leads to (on average) 94 out of 256 chambers containing a single cell.

The cell-suspension tube does not need to be placed onto the isoCell bed at the beginning of the plate program. Rather, best practice is for the user to agitate the sample until the isoCell prompts the user to place the tube onto the bed. This helps to prevent the cells from settling, thus maximising the adherence to Poisson statistics.

For higher throughput, up to four dishes (with pre-formed GRIDs) can be plated sequentially in a single run of the plate program. It is not necessary to use the same cell-suspension for all dishes when plating sequentially, since the dispensing system is washed and sterilised between dishes.

Input data

Once cells have been plated into chambers, the chambers that contain single cells need to be identified, and the corresponding GRID-coordinates need to be determined.

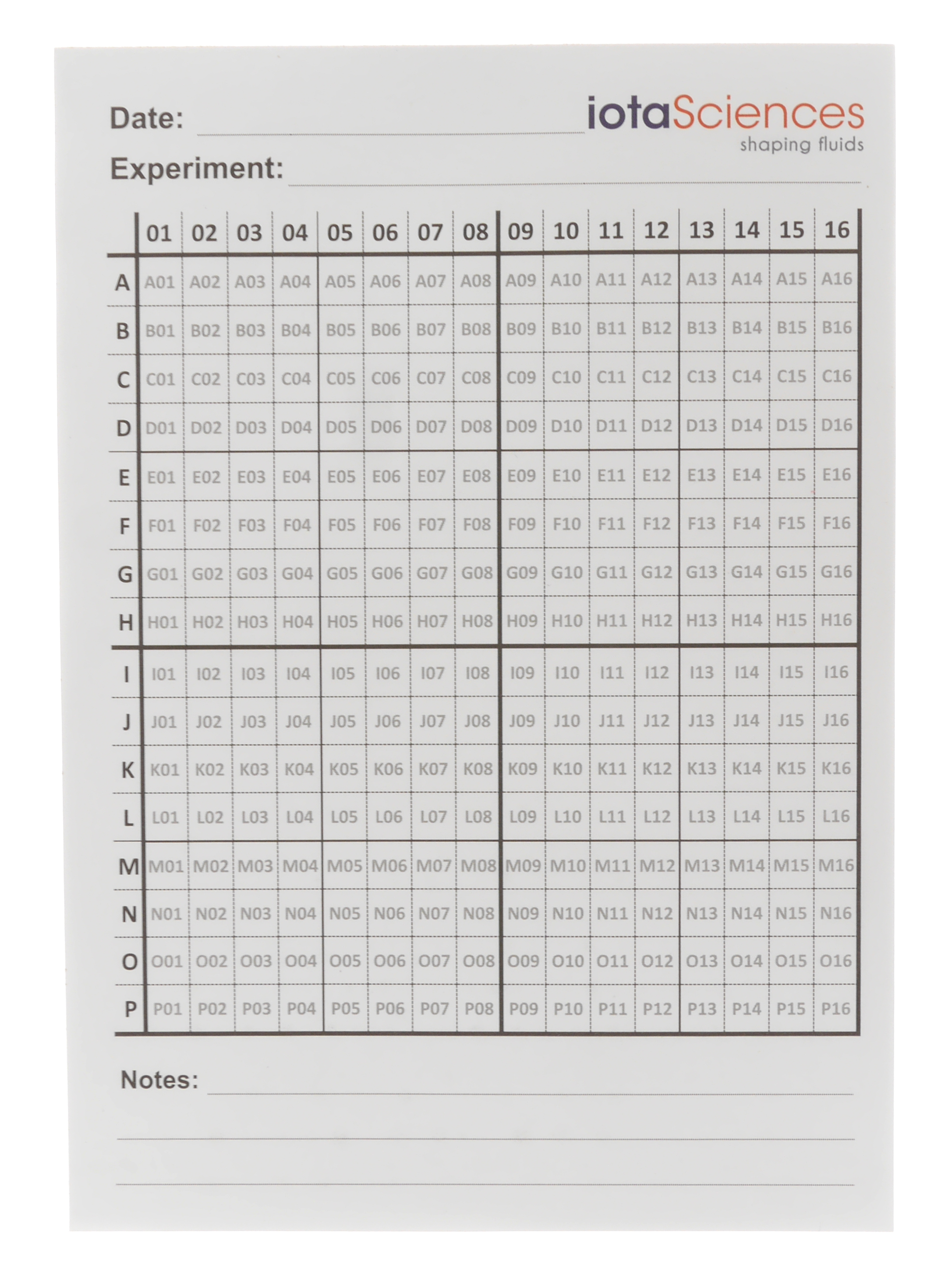

This is facilitated through use of the reference stage (supplied), on which each chamber’s GRID-coordinate is etched. Remove the plated dish from the isoCell, and place it on the reference stage, ensuring that the triangular protrusion of the locating ring fits into the triangular notch of the reference stage. Using a microscope, identify the GRID-coordinates of all chambers containing a single cell.

A single-cell microscope notebook is supplied for ease of recording GRID-coordinates of single-cell chambers. Once exhausted, fresh notebook pages can be downloaded for printing from the iotaSciences customer portal.

Once the GRID-coordinates of single cells have been determined, the input data program is used to store these coordinates in the isoCell’s memory. The stages in the program are as follows:

Select user. The user should select their own username. If the user is using the isoCell for the first time, they will have to enter a new username at this point.

Select colour. The user needs to select the colour of the locating ring attached to their dish.

Select chambers. The user needs to select coordinates of all chambers containing a single cell.

Press the

button to save data.

button to save data.

The isoCell supports up to thirty-six users. Under each username the isoCell can simultaneously track up to nine individual dishes via the dishes’ coloured locating rings. Stored user data can be managed via the data program.

Culture

Two programs are provided for the culturing of single cells into monoclonal colonies: fill and feed.

Fill

The fill program is used to top up each chamber containing a single cell from 200nl to 800nl. This must be the first program that is run on the dish following the input data program.

Feed

The feed program is used to remove 800nl waste from each monoclonal chamber, and replace the removed fluid with 800nl fresh media. The user may run this program as often as they deem suitable.

The feed program should not be run on a dish containing suspension cells – this would result in the cells being removed along with the 800nl waste.

Harvest

Two programs are provided for the harvesting of colonies: detach and extract. The user can select up to sixteen colonies to harvest per run of the detach and extract programs.

Detach

The detach program is used to deliver dissociation reagent to the selected chambers. It will first wash the chambers twice with PBS, after which it will dispense 800nl of dissociation reagent to each chamber.

Following a run of the detach program, the user should return the dish to the incubator for a suitable time period to allow the dissociation reagent to take effect.

The detach program should not be run on a dish containing suspension cells – this would result in the cells being removed during the PBS washes.

Extract

The extract program is used to remove selected colonies from the dish. It can be run alone (for suspension cells), or following a run of the detach program (for adherent cells). The extract program will deliver each selected colony separately into one tube of the two 8-tube PCR strips (or flat bottom 8-well strips) located at the front of the bed (Figure 2).

The user must first prepare the strips by depositing 120µl cell culture medium into each tube/well.

Do not put caps on the PCR strips.

Chamber states

As a dish progresses through the workflow, the isoCell tracks the state of the chambers. The current state of chambers in a dish is displayed at the beginning of the input data, fill, feed, detach and harvest programs, and can be viewed at any time via the data program.

The chamber states are:

| Non-clonal – Chamber contains either no cells or multiple cells. This is the default state – a chamber is assumed to be non-clonal until it is marked as clonal unfilled via the input data program. |

| Clonal unfilled – Chamber contains a single cell (or its derivative monoclonal colony). Chamber volume is 200nl, indicating that the fill program has not yet been run on the dish. |

| Clonal filled – Chamber contains a single cell (or its derivative monoclonal colony). Chamber volume is 800nl, indicating that the fill program has been run on the dish. |

| Detached – Dissociation reagent has been administered to the chamber using the detach program. |

| Harvested – The colony has been harvested from this chamber using the extract program. |

| Inactive – The cell or colony in this chamber is no longer active in the single-cell cloning workflow. Chambers can be marked as inactive at the beginning of the feed program. |

| Unknown – The chamber is in an unknown state. This can happen if, for example, a program is cancelled while operating on the chamber. The recover program can be used to attempt to return these chambers to a clonal filled state. |

The isoCell does not record the number (if any) of times the feed program has been run on a dish. The feed program will operate on chambers in a clonal filled state and will return them to a clonal filled state.

Advanced programs

Data

The data program (more → data) enables the user to:

Add or remove usernames.

View current chamber states of dishes.

Erase data of individual dishes under a chosen username.

Removing a username will erase all stored dish data for that username.

Options

The options program (more → settings → options) allows the user to:

Adjust display screen brightness

Adjust brightness of lights

Adjust volume

Turn bed heater on or off

Set time

The set time program (more → settings → set time) is used to update the date and time on the isoCell.

Replace dispensing

The replace dispensing program (more → replace dispensing) guides the user through the replacement of the dispensing assembly (dispensing needle plus tube). For more information, see replacing the dispensing assembly.

This program will automatically charge the new dispensing assembly with ethanol, and calibrate the new dispensing needle.

If the dispensing assembly has been replaced without running the replace dispensing program, the reset dispensing program must be run to charge the new assembly with ethanol. And the calibrate program must be run to calibrate the new dispensing needle.

FC40star® level

The FC40star® level program (more → FC40star® level) is used to update the tracked level of FC40star® in the FC40star® bottle (located at the rear of the isoCell). To update the level, move the slider to the correct height, and press the ![]() button to save.

button to save.

See Refilling FC40star® for more information.

Reset jetting

The reset jetting program (more → reset jetting) is used to completely flush and refill the jetting system.

Reset dispensing

The reset dispensing program (more → reset dispensing) is used to completely flush and refill the dispensing system.

Users should immediately run the reset dispensing program if a program that uses the dispensing system has been aborted prematurely. This will ensure that all reagents are quickly flushed from the dispensing system.

Recover

The recover program (more → recover) is used to attempt to recover any chambers from an unknown state to a clonal filled state (see chamber states).

The program will operate on all chambers whose state is unknown. It will remove 800nl fluid from each chamber, and replace the removed fluid with 800nl fresh media.

The recover program is not guaranteed to successfully return colonies to a useable state. If (for instance) chambers were left in an unknown state following an abort of the detach or extract programs, the colony may be physically detached from the dish. In which case, the removal stage of the recover program will likely remove and discard of the colony.

Calibrate

The calibrate program (more → calibrate) is used to calibrate the dispensing and jetting needle positions relative to the centre of the isoCell bed. It can be used if either of the isoCell’s needles has been replaced, to ensure continued performance of the isoCell.

Needle calibration happens automatically during the startup and restart routines, and when replacing the dispensing assembly using the replace dispensing program.

Move

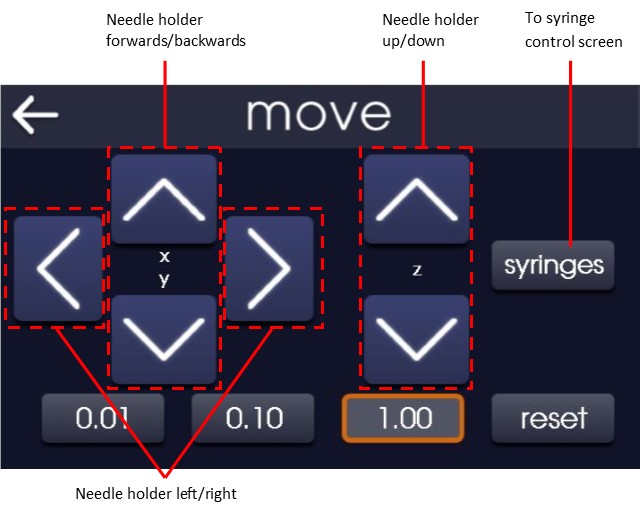

The move program (more → move) is used to:

Manually move the isoCell’s needle holder using the six arrow buttons indicated in Figure 3a. To return the needle holder to its home (not in use) position, press the reset button.

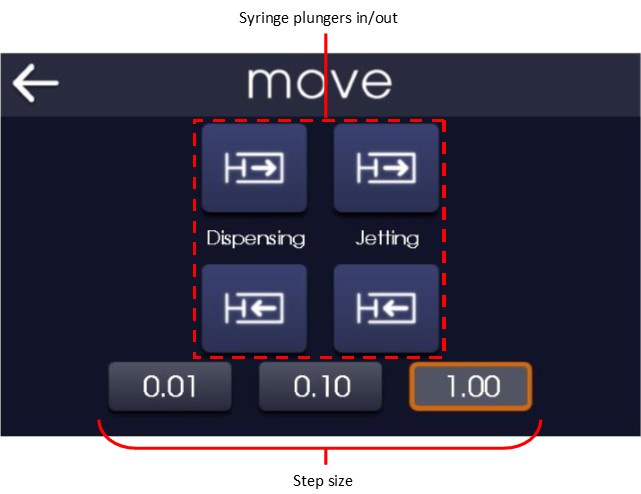

Manually withdraw or insert the plungers of the dispensing and jetting syringes, using the four buttons indicated in Figure 3b.

The movement step size is set using the three buttons indicated in Figure 3b. Step sizes are in millimetres for the needle holder and microlitres for the syringes. With the step size set to 1.00 the move buttons will cause large/fast movements, whereas with it set to 0.01 the move buttons will cause small/slow movements.

About

The about program (more → about) displays:

The software version number currently installed on the isoCell

Contact details for iotaSciences

Maintenance

Cleaning

Users are recommended to clean the exterior of the isoCell regularly, ideally before and after each use. iotaSciences recommend the use of a paper towel, dampened with 70% ethanol.

Do not attempt to manually clean the needles, which are delicate and easily damaged. The isoCell programs, if followed correctly, will ensure that needles are kept clean.

Care should be taken to ensure that excessive volumes of cleaning fluid are not used on the isoCell, as excess fluid entering the isoCell may lead to degraded performance or electrical safety risk.

Refilling FC40star®

FC40star® is stored in the FC40star® bottle, located on the rear of the isoCell (Figure 1). The isoCell tracks the level of FC40star® stored in this bottle, and will prompt the user when a refill is needed. Note that the isoCell cannot sense the FC40star® level; rather the current level is stored in the isoCell's memory. Following any program that uses FC40star®, the tracked level is updated in the isoCell's memory.

To refill the FC40star® bottle, completely unscrew the two-port cap from the bottle. Top up by carefully pouring fresh FC40star® into the bottle. It is not necessary to remove any residual FC40star®.

Having topped up the bottle, replace the two-port cap. Then use the on-screen interface to update the tracked FC40star® level. Alternatively, the tracked FC40star® level can be updated at any time using the FC40star® level program.

Ensure that the FC40star® intake tube is submerged at the bottom of the FC40star® bottle.

Replacing the dispensing assembly

The dispensing assembly (dispensing needle plus tube) should be replaced every eighteen dishes. Two fresh dispensing assemblies are included in every consumables kit.

To replace the dispensing assembly, run the replace dispensing program and follow the on-screen instructions.

Troubleshooting

Problems encountered during programs can often be traced to a small number of common issues. Please ensure the following:

Reagent microcentrifuge tubes are in place, open, and contain at least 1ml reagent (see isoCell bed).

Dish is seated flat on the isoCell bed, oriented such that the triangular protrusion of the locating ring fits into the bed's triangular notch (see isoCell bed).

FC40star® bottle (on rear of isoCell) is not empty. FC40star® intake tube must be submerged in FC40star® at the bottom of the bottle.

Dispensing syringe does not contain air. Use the reset dispensing program to flush any air from the syringe.

Jetting syringe does not contain air. Use the reset jetting program to flush any air from the syringe.

Needles are properly calibrated. Use the calibrate program to ensure this.

Should your problem still be unresolved, please contact iotaSciences technical support by raising a support ticket via the iotaSciences customer portal

Disposal and recycling

Disposal of isoCell

EU Waste Electrical and Electronic Equipment (WEEE) Directive

| In August of 2005, the European Union (EU) implemented the EU WEEE Directive 2002/96/EC and later the WEEE Recast Directive 2012/19/EU requiring Producers of electronic and electrical equipment (EEE) to manage and finance the collection, reuse, recycling and to appropriately treat WEEE that the Producer places on the EU market after August 13, 2005. The goal of this directive is to minimize the volume of electrical and electronic waste disposal and to encourage re-use and recycling at the end of life. |

Iota Sciences Ltd has met its national obligations to the EU WEEE Directive by registering in those countries to which Iota Sciences Ltd is an importer. Products bearing the symbol of a strikethrough refuse bin must not be disposed of along with unsorted refuse.

To dispose of your isoCell at the end of its useful life, please contact iotaSciences for the correct procedure.

Users outside the European Union

To dispose of your isoCell at the end of its useful life, please refer to your local waste management organisation for proper disposal practices for used electronic and electrical equipment.

Disposal of FC40star®

Dispose of waste FC40star® in a permitted industrial waste facility. Combustion products will include hydrogen fluoride. The facility must be capable of handling halogenated materials. Empty and dry product containers may be disposed as non-hazardous waste. Consult your specific regulations and service providers to determine available options and requirements. Refer to the FC40 material safety data sheet for more information, which is provided on the on the iotaSciences customer portal.

FC40star® must not be discarded into municipal drains/sewers.

Disposal of reagents and consumables

Used reagents and consumables (other than FC40star®) should be discarded in a suitable biohazard container. Refer to your local waste management organisation and to the relevant laboratory safety instructions for proper disposal practices.

Technical support

For technical questions, support issues or sales, contact iotaSciences via the contacts below:

Iota Sciences Ltd

Begbroke Science Park

Begbroke Hill

Woodstock Road

Yarnton

Oxfordshire

OX5 1PF

UK

Support Email: techsupport@iotasciences.com

Sales Email: sales@iotasciences.com

Website: https://www.iotasciences.com

Customer portal: https://portal.iotasciences.com

Please have the serial number of your isoCell available when contacting Technical Support.

Date of purchase:

Place purchased:

Serial number (located on rear of isoCell):

Additional information

Limited warranty

Iota Sciences Ltd sells the isoCell with a one-year warranty from the date of delivery against defects in design, materials and workmanship. If this product is found to be defective within that time, Iota Sciences Ltd may, in its sole discretion, at no additional or delivery cost, either repair or replace the unit, provide replacement parts, or issue a full refund and rescind the contract. This warranty does not cover accidental damage, wear and tear.

Please refer to our full terms and conditions (as applicable at the time of purchase) for more information on the exact scope of the above warranty. In case of any discrepancy between the above warranty and said full terms and conditions, said full terms and conditions will take precedence.

To make a warranty claim, please contact Iota Sciences Ltd at techsupport@iotasciences.com before returning your instrument to us.

Limited liability

To the maximum extent permitted by law, unless otherwise stated in our terms and conditions:

Iota Sciences Ltd expressly excludes any liability, whether in contract, tort (including negligence), for breach of statutory duty, or otherwise, arising under or in connection with the purchase of this instrument for loss of profits, loss of business, loss of revenue, loss of agreements, loss of contracts, loss of good will, loss of use or corruption of software, data or information or any indirect or consequential loss.

The company’s maximum aggregate liability arising out of or in connection with the agreement, or any product or service, shall be limited to the amount paid by the buyer to the company for the product or service purchased.

Please refer to our full terms and conditions (as applicable at the time of purchase) for more information regarding the above.

Please also note that any scientific information/protocols contained herein is believed to be correct and corresponds to the latest state of scientific and technical knowledge. However, no warranty is made, either expressed or implied, regarding its accuracy or the results to be obtained from the use of such information. Any user must make their own determination and satisfy themself that the information and recommendations given by Iota Sciences Ltd or its affiliates are (i) suitable for intended process or purpose, (ii) in compliance with environmental, health and safety regulations, and (iii) will not infringe any third party’s intellectual property rights.

Medical use restrictions

The isoCell is intended for research use by professionals only. The isoCell is not intended to be used for diagnostic purposes, or for testing or treatment in humans.

Registered office

Iota Sciences Ltd

Begbroke Science Park

Begbroke Hill

Woodstock Road

Yarnton

Oxfordshire

OX5 1PF

UK

Legal information

The Company reserves the right to update user manuals at any time without notice and the recipient is strongly encouraged to regularly check for updates on the iotaSciences customer portal.

The isoCell is manufactured by Iota Sciences Ltd, Begbroke Science Park, Begbroke Hill, Woodstock Road, Yarnton, Oxfordshire, OX5 1PF, UK.

All trademarks herein are marks of Iota Sciences Ltd.

©Iota Sciences 2019. All rights reserved.